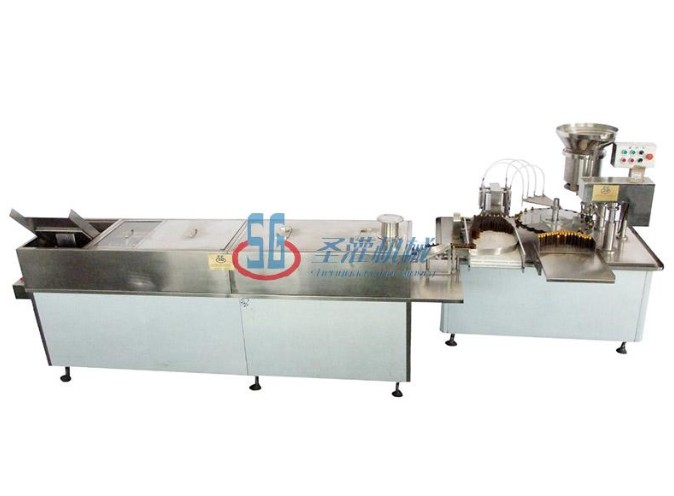

Production linkage of SGKGZ-4 type oral liquid

Production line introduction and introduction:

this unit is the main equipment of 10-30ml control bottle oral liquid liquid filling production line. It is composed of bottle washing, drying machine and filling and sealing machine. It can complete the action of bottle washing, drying, filling and sealing of oral liquid bottle. It is the most ideal supporting equipment for the manufacturer of oral liquid. This equipment fully meets the requirements of GMP.

features:

1. is accurate in volume and eliminates leakage. The precision of filling is high.

2. variable frequency variable speed, adjustable production speed, you can choose different production speed.

3. all electrical components are imported well-known brands.

4. imported PLC control, high degree of automation.

5. touch panel operating panel, convenient and beautiful.

6. automatically displays the counting function.

7. control adopts SIEMENS PLC, anti-interference and stable operation.

8. tracking defoaming filling, no foaming, metering accuracy. The performance of

9. is stable and the maintenance is convenient.

10. the whole machine is made of SUS304 stainless steel and 316L stainless steel. The whole machine is designed according to the requirements of GMP.

technical parameters:

applicable specification: 10-30ml

production capacity: 60-85 bottle / minute

drying temperature: 100-150 degree

back water flow: 0.5m water /h

purification water consumption: 0.3m /h

/h

purification compressed air consumption: 0.4m /min

/min

loading accuracy: less than 1

Copyright ? 灌裝生產(chǎn)線官網(wǎng) 滬ICP備17000578號-2